The below photo is of a typical “rebuilt head”. Most rebuilt heads have had new valve seats installed. The problem with having new valve seats installed is they always come loose someday. When I was a kid a few decades ago, my boss in the VW shop said “We don’t use rebuilt heads”. I asked why. He said “Because the seats fall out”. Some things never change. No one knows when and no one knows which one but it will happen. The loose seat was on number 3 cylinder. It had 120 pounds compression. The valve held it in place and apparently it “sealed” when the valve spring mashed it against the seat. Yeah, good compression with a removable seat. I could hear the air from number 3 being pushed backwards through the intake manifold.

The only way to find this problem without a trained ear is with a leak down test. This requires removal of spark plugs then an air hose is inserted into the spark plug hole (a fitting is required). The piston for the cylinder must be at TDC on the ignition stroke. In othere words the piston must be up and the valves must be closed. You may have to hold the engine from turning when the air is turned on. Or, take off the rocker arms entirely. With the air on, one listens. I one hears air coming from the tailpipe, it’s leaky exhaust valve sealing. If one hears it in the intake (take off air cleaner), it’s leaky intake valve sealing. If it’s a piston, you’ll hear it in the oil filler or the breather hose but leak down tests are most helpful for leaky intake valves. You’ll always hear something with the oil cap off because rings have gaps and a tiny amount of air always leaks hear. With perfect head sealing, you’ll hear nothing in the exhaust pipe or the intake manifold. The only thing that’s acceptable is a tiny hiss listening through the oil filler with the cap off (or on, I guess) coming from the ring gaps. This is entirely normal. Type 4 engines are most likely to have this problem because they are the only air cooled VW engine that uses a 30 degree angle for the valve seat. All other valves on all models use the more effective 45 degree angle however, with proper seat and valve grinding, type 4 intake valve sealing lasts a real long time.

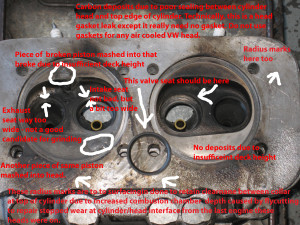

This problem can make your fuel injected vehicle real hard to start at times and easy at others. The reason is because the air flow sensor doesn’t measure the air coming backwards out of the seat and being sucked into another cylinder so the mixture is wrong. On a carbureted vehicle, mashing the pedal a few times adds fuel to the system and the vehicle stars. You can pump the pedal on a fuel injected vehicle a thousand times and it won’t make any difference – nothing comes out. After the valve in head in the photo below was removed, the seat came out with my finger – no tools, no hammering required. Number 4 – right next to it – had a broken piston. You can see the pieces of it mashed into the head.That’s because no one checked the deck height. Typical “Lego Toy” assembly of some expensive engine parts – heads, pistons – stuff like that. And never use rebuilt head that have had new seats installed unless you’re a gambler. If you’re building a stock engine and you check the compression ratio and adjust it (if necessary, using shims), the chances of your pistons hitting the head and slim to none. You’re deck height will automatically be right due to you’re diligence and the shims you install providing they’re needed. If you don’t need shims and the ratio is right by the book, the chances of this problem occurring are very slim too. Always check the compression ratio when building any engine for any vehicle.

This is a typical type 4 engine rebuild. It’s in an 80 Vanagon. The person who bought this engine thought he was getting a deal. About $1800. He wasn’t. A nice type 4 rebuild can cost five grand – installed of course, and with the assembly performed in the non-Lego Toy style. New heads are expensive and the non-Lego Toy assembly method takes much longer than the Lego Toy assembly method. You may think five grand is expensive. Ok. Then you must think that throwing $1800 into the toilet is a bargain. This engine didn’t even have 6000 miles on it. It leaked at every possible place, it was often hard to start, it was very noisy (some genius thought putting solid lifters in an originally hydraulic engine was a good idea). But most of the noise was from the pistons getting so close to the head (see photos). This causes noise too. The intermittent hard starting (needed lot’s of cranking at times – like a minute – to get it started when it died in an intersection due to trying to take off in second and not knowing it, for instance). This overwork due to leaky intake valves killed the started but the improperly machined flywheel may have an an effect on the starter in that the starter would grind on the flywheel rather than engaging. The flywheel tooth damage and grinding starter may also be a result of the flywheel turning person ground the outer face of the flywheel making the teeth narrower thus harder to engage with the starter. I’ll buying another hopefully virgin flywheel to compare. Flywheel turning on any air cooled VW is seldom necessary and should be avoided at all costs. Small grooves on the friction surface are ok. Check the end play shim mating surface for damage. Look at the teeth. Minor damage is ok. A groove on the flywheel sealing surface is ok. Minor rust pitting here is ok, deep pits will leak. This is s judgement call.

Here’s the piston that broke. Not all of the pistons were broken but they were all “clean” as in minimal carbon deposits because the Lego Toy assembler didn’t check the deck height and thus didn’t check the compression ratio either and the pistons closer to the head at TDC than the depth of what should be a carbon deposit so the were constantly smashing it off. Any piston could have failed since they were all like this but this is the one that just couldn’t take it anymore. This cylinder had 60 pounds compression.

Although there is some carbon, you can see that where the piston is closest to the head there is none and what’s there is real thin. It’s merely incidental.

Here’s a new head made by AMC of Spain. I’ve never seen one of these heads with a loose valve seat but I’ve seen these heads destroyed for a lot of other reasons and it’s all due to assembly error – usually the Lego Toy method of assembly.

A new head is significantly more expensive than a rebuilt head so most rebuilt engines get rebuilt heads – particularly type 4 engines.

Here’s used type 1 dual port genuine head with original seats …

I would not throw this head away. I would use it on the passenger side, not on number 3 side … just because. With proper seat cutting, and nice valve guides, it should seal well at least 40, 000 miles on a vehicle that is not abused (bus driven at 70 mph every time one gets on the freeway for instance).

I would not throw this head away. I would use it on the passenger side, not on number 3 side … just because. With proper seat cutting, and nice valve guides, it should seal well at least 40, 000 miles on a vehicle that is not abused (bus driven at 70 mph every time one gets on the freeway for instance).

Here’s a used genuine type 4 head – note the VW part number. It may have a VW emblem on it somewhere but all genuine heads have a 9 digit VW part number cast into the head in the rocker arm area …

And here’s a new AMC head in the box …

And here’s the other rebuilt head from the 1/2 side of the motor with the removable seat …

How to decide if you should use a head again – if the seats have been replaced, throw it away. If it’s cracked anywhere except between the seats, throw it away. If it needs an insert to repair a stripped plug thread, you can use it but if the insert fails down the road, repairing a spark plug hole the SECOND TIME is seldom a long term fix. For best results, use a head that needs no or has no plug inserts. That way, if a plug hole does strip in the future, you’re putting the first insert in and it’s usually viable for a long time. Also, the seats on your used head must be grindable or you need another head.

There are two reasons what should be junk heads get seats replaced and have welding performed on them. One, new heads are more expensive than rebuilt heads and the other is that a head with a crack or one that needs seats still looks real nice – it looks like a head. It’s just too pretty to throw away. But you have to.

So if your heads just need guides and valves, the original seats are grindable and there are nor cracks in the bad places, you can have it “rebuilt’. But the typical rebuilt head with new seats is not a viable long-term fix. It’s just a gamble. Do you really want to gamble on that trip you’ve been planning to Alaska for the last five years? Nice used heads that meet the criteria are viable for the long term.

When you look at your type 4 motor’s heads, if they’re genuine, most likely they’ve had the seats replaced. You can’t tell unless you look at them meaning remove head to look. Realize, genuine type 4 heads are most likely at least as old as the vehicle unless it’s a 72 bus or an early type 4 sedan. The dealer seldom used new ones, and they offered their own rebuilts. Some had new seats installed (bad), some didn’t. So a rebuilt head using a genuine head could be over 40 years old, could’ve been on numerous vehicles and could’ve been rebuilt ten times. Seats that have been replaced are larger in diameter than an original seat. The ones in the heads shown above are bigger than typical replacement seats thus those heads have probably had the seats replaced more than once requiring bigger hole to be made in the head each time the seat is replaced. And there’s no telling how much metal has been machined anywhere and evidence of welding is a deal breaker too. Welding always cracks. Just don’t do it. Buy new or find nice used ones that have never had the seats replaced. Look for cracks everywhere including the area where the rockers go. Valve guide bosses can be cracked too. The only crack that’s ok on any air cooled VW head is the one shown above found between the seats. All others render the head junk.

New genuine heads for type 1 applications are still available. There is also the Auto Linea brand from Brazil for type 1. The seats don’t last like genuine so use new or nice used genuine when you can. Many air cooled VW heads are being made in China now. They, as all new heads of any kind, require a trip to the machine shop to have the seats checked an likely “cleaned up” for good sealing. Always use fluid like solvent or gasoline to check for perfect sealing after seat work or seat clean up. Just pour it in the combustion chamber. Even with competent grinding of the seats, you may have some leakage. Try hitting the valve with a big hammer a few times to open the valve momentarily. It won’t hurt anything. You’re mimicking what the rocker arm does. This may fix it. If not, lap the valve in question. I lap all valves after grinding. Most machinists will tell you this is not necessary. I don’t agree.

Any high performance head with bigger valves has had bigger seats installed. High performance may not necessarily result in long term reliability. Only seats with original factory peening be it AMC or genuine have maximum reliability.

With perfect valve sealing and proper assembly and good parts, you’ll get the results you expect, not what you end up with.

New genuine heads with long reach plugs available currently do not have peening. Will these seats come loose? We’ll find out.

This entry was posted on Sunday, March 16th, 2014 at 9:33 pm

You can follow any responses to this entry through the RSS 2.0 feed.

- We are in no way affiliated with Volkswagen

- Copyright © 2024. All Rights Reserved