The generator turns about 75 percent faster than the engine. At 4000 rpm at the engine, the generator is turning at 7000 rpm. That’s real fast. And since the generator is the cooling system, it has to be as reliable as the engine. Engine bearings are lubricated by a constant supply of oil pumped to them. The generator has permanently sealed ball bearings. It’s amazing how long they last. To check them, remove the belt and spin the generator with the pulley. The only thing you should hear is nothing – silence. If you hear anything, it may be the generator brushes rubbing on the commutator. You can lift the spring away from the brush and lay the brush away without even removing the screw. Then spin it. Now you should hear nothing. If you hear no rumbling sound, your generator bearings are good. You may hear the fan scraping on the fan housing. Loosening the generator strap and attempting to slide the generator in or out may solve this. Loosening the fan housing securing screws may help with this. Fan removal and adjustment with shims may be necessary. Overall, you should hear nothing when you spin a generator or alternator on any vehicle.

The generator pulley must be secured perfectly for long term, reliable cooling, generator life, and belt life.

The belt should ride somewhat deep in the pulley like this …

If the belt is flush with the edge of the pulley, it’s possible for it to fly off at typical highway speeds. It must be engaged a bit with the pulley.

The pulley needs to be tight …

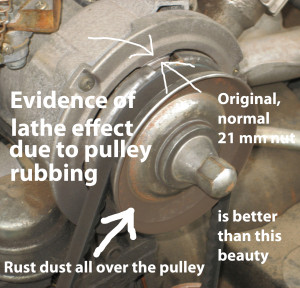

and it can’t rub on housing …

More pulley rubbing …

To solve this problem, use these washers between the spacer and the pulley …

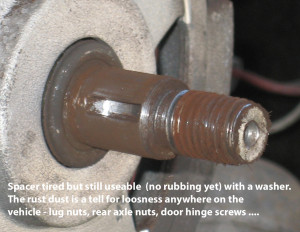

The thinner the washer the better. You may have to file slightly to make it fit over the shaft. If the washer rubs on the housing, the spacer is too worn to use. You’ll have to find another one and you may have disassemble the generator/alternator to install it but you may be able to convince it to come out without disassembly. The only place to get one is from a used generator/alternator (alternator and generator spacers are the same). You can’t buy this part by itself.

The pulley should slide on and off the shaft with no effort. Put the inner half of the pulley on backwards (easy to deal with backwards) using WD-40. Make sure it spins freely on the shaft. You may have to clean up the shaft with file. Once it’s easy to put on and off, install it with washer if necessary using diluted anti-seize compound on the shaft. With a new belt, use at least 5 or 6 shims in between with at least 3 or 4 on the outside for spares. If you find you only have 2 shims in between with a new belt, your belt is too long. For 12 volt systems, a 9.5 X 905 millimeter belt is correct but it’s not uncommon to have only 2 shims left with proper adjustment. In this case, try a 6 volt 10 X 900 millimeter belt. You may end up with 5 or 6 shims in between pulley halves which enables you to adjust the belt a few times in the future. With only 2 shims, you’ll need a new belt in a week if you want proper adjustment. If neither the 12 or 6 bolt belt seems short enough to end up with about 6 shims in between pulley halves, you’ll need shorter one. Just a few millimeters makes a big difference. Usually somewhere between 890 and 900. Consult your local auto parts store. There’s a zillion belts available. The salesperson should be able to help you find something that will work. You may need to make a couple trips to the store (trial fit).

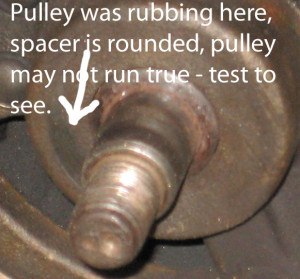

The reason the spacers in generators and alternators get rounded is because of poor quality pulleys like this one …

Here’s more pulleys …

There’s nothing like a genuine part.

There’s nothing like a genuine part.

Rusty shims and pulley mating surfaces should be sanded with WD-40 and sandpaper to smooth them out for perfect mating. Spray them and the pulley mating surfaces with WD-40 upon installation (with everything slippery, everything will mate real well) and used diluted anti-seize compound on the shaft when installing. With too few total shims (doesn’t matter whether they’re in between pulley halves or under the nut, without enough, the assembly will wiggle (assemble without any shims or the belt to understand this point). Put the nut on – preferably the original style 21 millimeter nut – REAL TIGHT.

You cooling system is now bulletproof.

This entry was posted on Friday, October 10th, 2014 at 8:13 am

You can follow any responses to this entry through the RSS 2.0 feed.

- We are in no way affiliated with Volkswagen

- Copyright © 2024. All Rights Reserved