How to make the latest “European” muffler actually fit and/or how to put a muffler on a VW so it does everything it’s supposed to do and LASTS.

Preparing Muffler for Installation

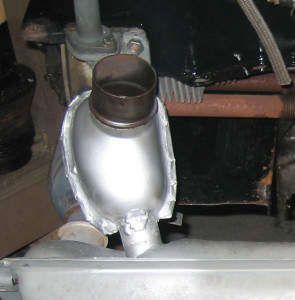

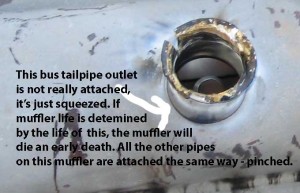

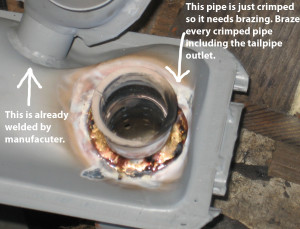

All the pipes on an original muffler are welded to the muffler itself. All the aftermarket mufflers made for bugs to 74 and buses to 71 are crimped. This is because it’s cheaper than welding. But basically what yo’re getting is not a one piece muffler but an assortment of pieces poorly attached to each other by simply squeezing the metal around them like this …  And here a genuine Volkswagen muffler designed for a Volkswagen by Volkswagen …

And here a genuine Volkswagen muffler designed for a Volkswagen by Volkswagen …

Here’s a genuine VW 40 hp muffler – look at those welds. They’re on every pipe. If you want long, trouble free, fumeless operation from you exhaust, you’ll never get it with a crimped muffler. Weld it or braze it. And weld it to the heater boxes. That’s also part of the equation.

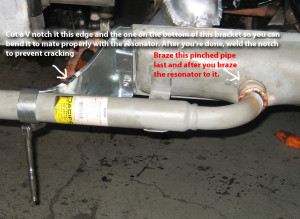

And here’s what you need to do to make any squeezed together muffler last and last until it rusts away or cracks vertically on the engine side in the middle of the muffler – one or the other. These to failures are organic failures – death due to old age. Anything else is death to to poor engineering – inorganic failure because broken pipes don’t have to happen if you weld or braze …  I like brazing myself because you can undo brazing but you can’t undo welding and it does’t heat the muffler so much. It’s also handy for brazing the bus resonator onto the muffler so if it needs replacing, you can unbraze it because this won’t work for long …

I like brazing myself because you can undo brazing but you can’t undo welding and it does’t heat the muffler so much. It’s also handy for brazing the bus resonator onto the muffler so if it needs replacing, you can unbraze it because this won’t work for long …  … only brazing will result in a solid, long lasting, non-leaking seal here. The asbestos doughnut seal will never last if it works at all unless you only drive to shows. I if you wanna fix it and forget it, braze this. Most likely, by the time the resonator is dead, the muffler will have either cracked in the front right down the middle or rusted away and until then, no fumes and no backfiring provide you follow all the steps that follow..

… only brazing will result in a solid, long lasting, non-leaking seal here. The asbestos doughnut seal will never last if it works at all unless you only drive to shows. I if you wanna fix it and forget it, braze this. Most likely, by the time the resonator is dead, the muffler will have either cracked in the front right down the middle or rusted away and until then, no fumes and no backfiring provide you follow all the steps that follow..

The Dansk Dance

Now on to the Dansk (Jopex) muffler. You’ll find this to be true upon trial fitting ….

You’ll find it either impossible to fit the fresh air hoses to the junction box or impossible to connect the junction box to the heater box.

If you want a lot of heat and no fumes (and a place to attach the fresh air hoses to) you’ll have to start here …

Uncrimp the junction box …

And attach it to the heater box with the proper strap/clamp …

and the lower half of the junction box to the pipe.

Do the same with the top half with the sheet metal in place to you can position it properly for the metal sleeve to fit through the hole in the sheet metal …

Then braze it in place …

Do the best you can re-crimping. You’ll need to braze some too. Whatever works. You’ll never make it perfect but do the best you can. Even genuine was not perfect regarding air tight. Spray with high temp paint.

The final result is this. Notice I had to beat on the top half of the right side junction box to make it behave. The look may not be concours but the heat will be …

Don’t forget to braze the pinched tailpipe outlet. You can do that later after you braze the resonator the the outlet. Do it on the car so you can be sure the tailpipe doesn’t hit the bumper on buses …

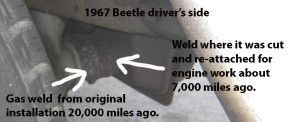

I didn’t forget the clamp because I don’t need it. The only way you’ll get a perfect seal here is with brand new Genuine VW Parts – means brand new genuine VW heater boxes, muffler and muffler to heater box clamp kits, or let the car sit for about 2 years – preferably in a damp climate. That way, the heater box pipe outside diameter gets bigger and the muffler pipe inside diameter gets smaller as the rust builds up over time. But if you want perfect, permanent hassle free sealing every time, gas weld it. Another benefit to gas welding is that the heat softens the metal while welding and this relieves all the stresses on the joints and thus on the body of the muffler itself. This yields maximum life expectancy that’s only limited by the steel itself and your workmanship. And case you’re thinking it – this is better than flanges which do have gasket sealing problems over time due to heater box j-pipe flexing resulting in wiping/sliding at the gasket (no gasket needed means no gasket to leak – Google Offfenhauser cylinder head, wikipedia) and as I said, the heat from welding in place relieves all stresses.

If you need to disassemble and use the same muffler, just cut the muffler pipe (close enough to the muffler so you don’t cut through the heater box pipe – about 3/4″ from the body of the muffler) with a Sawzall or a hacksaw and weld back together when done. If you need to replace the muffler, cut the pipes (again, close to the muffler so you don’t cut through the heater box pipe – about 3/4″ from the body of the muffler). Then peel the remnant from the heater box pipe with diagonal cutters (wire cutters). You’ll probably need to use a chisel too. But this works and when you’re done, you won’t even be able to tell it was ever welded. I use gas welding. Electric welding of any kind may not be able to be undone. I don’t know, I’ve never tried but I do know gas welding will allow you to remove the welds. The heater box material is an unusual alloy. Sometimes it’s hard to get gas welding to stick. Penetration will be poor but that’s ok. One side may even seem easier to weld than the other. But this does last. If you detect a leak at a weld in the future, just weld it.

Heater boxes have a J shaped pipe passing through them. Imagine the muffler is not on the car but the heater boxes are. Now think of the engine vibration and it’s effect on the J pipe – ask yourself how much the muffler end of the pipe would be moving up and down due to the vibration. Perhaps 1/8 – 3/4″ total amplitude at 3000 RPM. Now think of the effect of the force that this potential movement has on the pinched pipe that mates the heater box with the muffler. The heater box J pipe vibration acts like a machine designed to break the pinch. But if you braze/weld all the pinched pipes and weld the muffler to the heater boxes, the exhaust system becomes all one piece. And if you put the engine together non- Lego Toy style, everything “is all one piece”. You’ll have a complete, one piece Volkswagen powerplant. But following the above with respect to the exhaust will yield a quiet car, no backfiring and a fume free heater, and with stock heater boxes you can expect an outlet temp of over 160 F even on a cold night. So called “racing heater boxes” without fins on the pipes will result in a lower temp by at least 40 degrees. It’s not enough to heat a car on a cold night.

- We are in no way affiliated with Volkswagen

- Copyright © 2024. All Rights Reserved